Press Release

Publisher: Bachmann Monitoring GmbH

Bachmann Blade Bending Sensor Advances Predictive Maintenance in Wind

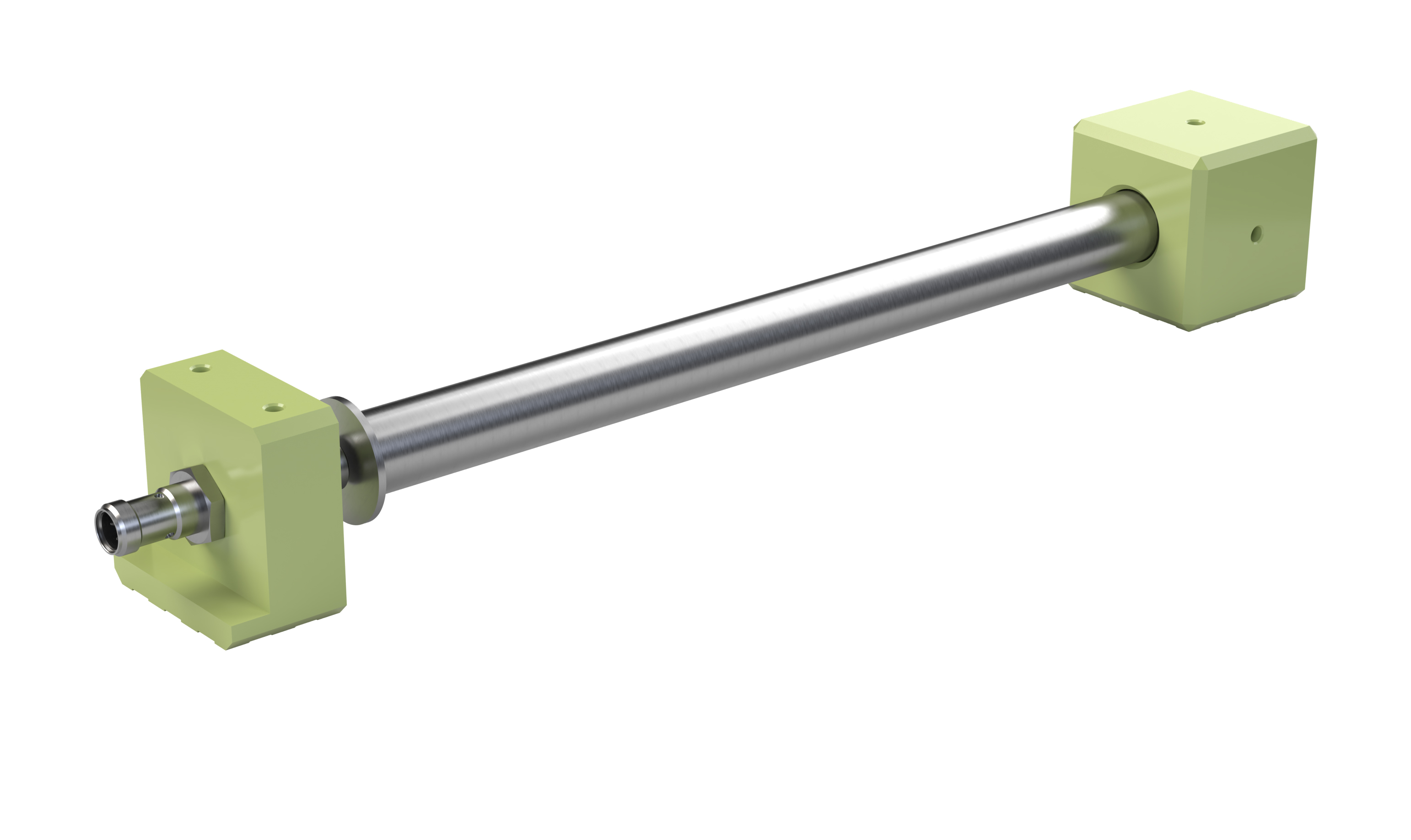

Cantilever Sensor (CLS)

© Bachmann electronic GmbH Rudolstadt, Germany (renewablepress) - Condition Monitoring experts, Bachmann Monitoring, reveal the next phase of wind turbine blade monitoring. The Cantilever Sensor (CLS), a state-of-the-art blade bending measurement technology, is a cost effective and accurate measure of rotor blade strain in real time. The robust CLS provides a wider range of values and is more durable than existing strain gauges. Easy to install, the sensor facilitates optimized pitch control with early ice and fault detection to improve predictive maintenance of turbine blades both on- and offshore.

An application of proven displacement measurement technologies, the CLS delivers precise measurements with very low tolerances (+/-0.5µm). Results are unaffected by local material inconsistencies due to a sample area over 12 times longer than existing gauges, and the titanium cantilever guarantees stability. Designed for harsh environments, the sensor’s non-contacting measurement technique increases long-term repeatability and durability over conventional strain gauges, making it a robust solution for modern wind farms.

“The Cantilever Sensor enables a range of new possibilities in predictive maintenance,” says Holger Fritsch, CEO of Bachmann Monitoring. “For example, an ice detection system based on CLS and SCADA data to improve safety. With two sensors on each blade, we can create an orbit to detect any changes as soon as they occur; an excellent indicator of blade condition. This is the future of Condition Monitoring and we are excited to be part of it.”

For more information, please visit:

https://www.bachmann.info/uploads/tx_sbdownloader/CLS_Cantilever_Sensor_en.pdf

Bachmann electronic GmbH

https://www.bachmann.info/en/bachmann/

About Bachmann electronic GmbH in the wind energy sector

Bachmann electronic, global automation experts with headquarters in Feldkirch, Austria, has been optimizing customer productivity and profit for 50 years. With more than 20 years’ experience in the wind market and as the leader in wind energy automation, Bachmann provides the highest quality, durability and reliability to one in three turbines worldwide.

Open and flexible communication standards, integrated machine health monitoring and web-based visualization are just part of the total solution Bachmann offers its customers. Continuous innovation and accumulated engineering know-how safeguard success and build trusted partnerships between Bachmann and its customers for generations to come.

Download press photo:

https://www.renewablepress.com/press-images/bachmann-monitoring/cd9fe_cls300_new.jpg

https://www.renewablepress.com/press-images/bachmann-monitoring/cd9fe_cls300_new.jpg

Caption: Cantilever Sensor (CLS)

© Bachmann electronic GmbH

Rudolstadt, Germany, 14 December 2020

Publication and Reprint free of charge; please send a voucher copy to Bachmann Monitoring GmbH.

Attention editorial offices - For further questions please contact:

Media contact:

Bachmann electronic GmbH

Corporate Communications

Tel: +43 (0)55 22 / 34 97-1282

E-Mail: presse@bachmann.info

Bachmann electronic GmbH

Kreuzäckerweg 33

6800 Feldkirch, Austria

Bachmann Monitoring GmbH

Fritz-Bolland-Str. 7

07407 Rudolstadt

Tel: +49 (0)3672/ 3186-0

Internet: https://www.bachmann.info/en/bachmann

Online press kit - all press releases from DE194889554

Press photos for editorial use only

Note: For the content of this press release the issuer / publisher of the release is »DE194889554« responsible.

The press release "Bachmann Blade Bending Sensor Advances Predictive Maintenance in Wind " von DE194889554 is also available in the following languages:

More press releases from Bachmann Monitoring GmbH

- Bachmann Monitoring Further Extends Condition Monitoring for Offshore Wind Turbines in the North Sea

About Bachmann Monitoring GmbH

Bachmann Monitoring GmbH develops, produces and markets innovative measurement systems and systematic solutions for the permanent condition based maintenance of wind turbines. This comprehensive service concept using manufacturer integrated or stand-alone condition monitoring systems substantially increases the reliability and profitability of the wind turbine.

The main area of business for Bachmann Monitoring GmbH is the measurement and online analysis of vibrations enabling the reliable monitoring of the majority of the drive-train components of onshore and offshore wind turbines. The remote condition monitoring via Weblog forms the basis of the efficient monitoring of decentralised plant equipment. The early recognition and localisation of possible weak points gives our customers the optimum availability of their plant equipment and increased long term profitability. The structure-borne sound based condition monitoring is complemented by diagnostic functions for imbalances, rotor blades and structural component monitoring. The range of services offered also includes the compiling of vibration reports.

Wind turbines with Bachmann control systems have the option of adding a comprehensive integrated “Omega Guard” condition monitoring system, which is also certified by “Germanischer Lloyd”. This solution offers significant cost and technological advantages when compared to the conventional stand-alone CM systems.

Press contact at Bachmann Monitoring GmbH

Frank Fladerer

Mail: frank.fladerer@bachmann.info