Press Release

Publisher: Deutsche Windtechnik AG

evoblade and Deutsche Windtechnik develop trailing edge spoilers for rotor blades

- study confirms flow improvement, load reduction and positive effect on entire service life

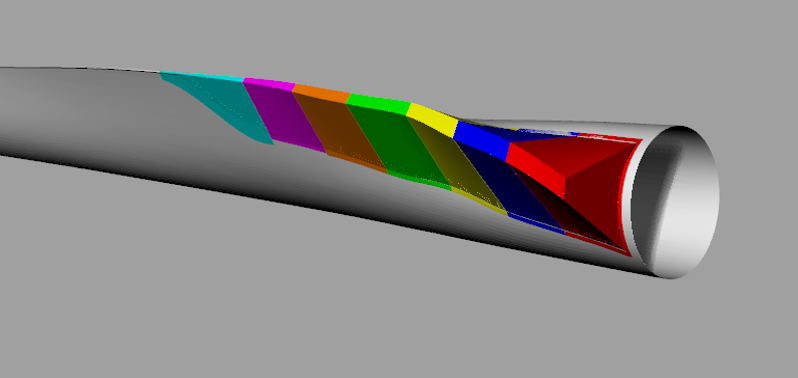

The trailing edge spoiler EvoFlap for the blade root area, divided into 7 segments.

© EvobladeBremen, Germany (renewablepress) - The wind energy start-up evoblade, a spin-off of the Institute of Aerospace Technology (IAT) of the University of Applied Sciences Bremen, has developed a retrofittable spoiler for rotor blades with the help of Deutsche Windtechnik and Wirtschaftsförderung Bremen. The results of a side-by-side study of testing and optimising the EvoFlap now confirm that installing the spoiler can improve the aerodynamic flow in the area of the blade root, resulting in improved efficiency and performance of the system.

"Rotor blades have a significant impact on the technical and economic performance of a wind turbine," said Dr.-Ing. Frank Kortenstedde, founder and CEO of evoblade. "By developing and optimising a retrofittable flow element, we wanted to achieve a technical and economic improvement in the properties of existing systems that leverages the advances in technical understanding." Matthias Brandt, Director of Deutsche Windtechnik AG, added: "Even though retrofitting flow elements is not always an option, and the initial design and features of turbines are up to the system manufacturers, we are still very happy to participate in and support research projects like this that look at technologies of the future. The results are moving in the right direction and are helping the entire industry!"

Side-by-side study design with iSpin performance monitoring

The EvoFlap can be adapted to different rotor blade types. The NEG Micon NM 82 turbine type with a rated output of 1.5 MW and a rotor blade length of 40 m was selected as the basic system for the optimisation. The flow element was developed using the GFRP sandwich technique and has an overall length of 10 m. It is divided into seven segments to allow assembly directly on an installed rotor blade. "The blade does not have to be removed from the hub to allow EvoFlap to be installed, and this reduces the amount of work and costs," Frank Kortenstedde emphasised. "Also, the blade structure is not damaged by gluing the segments onto it, and the EvoFlap blends harmoniously with the blade design." To validate the annual energy output, the company ROMO Wind was commissioned to carry out independent performance monitoring using iSpin spinner anemometer technology. Measuring the wind speed in front of the turbine has the advantage that the reference wind speed is measured directly and undisturbed. In addition to the test system, a second (adjacent) turbine of the same type was equipped with iSpin technology as a reference system.

Six percent additional yield and positive effect on service life

The results of the side-by-side study (project duration 08/2015 - 03/2019) confirmed the increase in AEP (annual energy production) that had been predicted using simulated data. Recent results also show a six percent increase in AEP with an average annual wind speed of 7 m/s. In addition to increasing the yield, it was demonstrated that the EvoFlap also increases the bending and torsion strength of the rotor blade, and this has a positive effect on the service life of the blade. "Depending on the useful life of the EvoFlap, a possible extension of 1.2 to 2.6 years beyond the maximum service life of 20 years can be achieved," Frank Kortenstedde explained. "A very high level of technology transfer has been achieved. Retrofitting such large-scale flow elements is currently the absolute exception. Nevertheless, this research project shows significant potential positive effects."

The EvoFlap can theoretically be installed on all wind turbines that have a slender design in the area of the blade root. The flow element is suitable as a retrofit solution or for manufacturers of wind turbines, but it needs to be adapted to the individual characteristics of the corresponding blade type.

About evoblade

evoblade is a spin-off of the Institute of Aerospace Technology. The close cooperation with the University of Applied Sciences Bremen and its research activities is the foundation of its competence, services and products. evoblade offers aerodynamic optimisation of rotor blades of wind turbines using the trailing edge spoiler EvoFlap. This patented technology can achieve a significant increase in the efficiency of wind turbines. The EvoFlap spoiler is individually developed and adapted for each rotor blade type to achieve the best performance improvement.

Contact for evoblade: Frank Kortenstedde

More information about evoblade and images for free editorial use: https://evoblade.de/projekte

About ROMO Wind

ROMO Wind is a technology and service company in the wind industry with headquarters located in Switzerland and branch offices in Germany, Denmark, France, Italy and Spain. ROMO Wind is specialised in precisely determining the wind conditions at wind turbines independently of manufacturers and optimising the productivity of wind turbines as well as minimising loads based on the data obtained. For this purpose, the company uses the patented iSpin® spinner anemometer technology, which is already used in more than 1.200 wind turbines, more than 70 different turbine types (onshore and offshore) and in more than 20 countries.

Contact for ROMO Wind: Marcus Müller

More information on iSpin technology and images for free editorial use: www.romowind.com

About Deutsche Windtechnik

Bremen-based Deutsche Windtechnik AG offers a single-source full technical maintenance package for wind turbines in Europe, the USA and Taiwan. The company operates both onshore and offshore. More than 5,800 wind turbines are serviced worldwide, by over 1,800 employees, under permanent maintenance contracts (basic and full maintenance). Its system engineering focuses on Vestas/NEG Micon, Siemens/AN Bonus, Nordex, Senvion, Fuhrländer, Gamesa and Enercon turbines.

Download press images:

https://www.renewablepress.com/press-images/deutsche-windtechnik/d3715_Bild1_flow_element.png

https://www.renewablepress.com/press-images/deutsche-windtechnik/d3715_Bild1_flow_element.pngCaption: The trailing edge spoiler EvoFlap for the blade root area, divided into 7 segments.

© Evoblade

Caption: Sectional view of the rotor blade looking at the nacelle from above, showing the reduced turbulence intensity with EvoFlap.

© Evoblade

Bremen, Germany, 02 February 2021

Publication and Reprint free of charge; please send a voucher copy to Deutsche Windtechnik AG.

Attention editorial offices - For further questions please contact:

Media contact:

Karola Kletzsch

Corporate Communication

Deutsche Windtechnik AG

Tel: + 49 (0)421 – 69 105 330

Mob: + 49 (0)172 - 263 77 89

Fax: + 49 (0)421 - 691 05 499

E-Mail: k.kletzsch@deutsche-windtechnik.com

Deutsche Windtechnik AG

Stephanitorsbollwerk 1 (Haus LEE)

28217 Bremen

Tel: +49 (0)421 69105-0

Fax: +49 (0)421 69105-499

E-Mail: info@deutsche-windtechnik.com

Internet: https://www.deutsche-windtechnik.com

Online press kit - all press releases from DE252570942

Press photos for editorial use only

Note: For the content of this press release the issuer / publisher of the release is »DE252570942« responsible.

The press release "evoblade and Deutsche Windtechnik develop trailing edge spoilers for rotor blades" von DE252570942 is also available in the following languages:

More press releases from Deutsche Windtechnik AG

- Change at the top: Deutsche Windtechnik sets the course for the future

- Deutsche Windtechnik (DWT) expands offshore management team with Achim Berge Olsen as new CEO

- Deutsche Windtechnik‘s Aircraft Detection Lighting System a success — new installations and international business on the horizon

- Deutsche Windtechnik is further expanding its training capacities – Training Center opens a new location with wind turbines in original condition

- All European units united under one umbrella: Deutsche Windtechnik creates new European holding company

- Deutsche Windtechnik Sweden develops first contract to extend the operational life of 23 Vestas V90 wind turbines to 30 years

- Joining forces: Deutsche Windtechnik and Meidensha Corporation unite to introduce independent onshore wind energy services to Japan

- Deutsche Windtechnik advances the Belgian wind energy sector by introducing independent wind turbine services

- Independently confirmed for the first time: TÜV NORD declares that the drone system used by the Deutsche Windtechnik Inspection Body is a valid solution for inspecting rotor blades and lightning protection systems

- Major order in UK: Deutsche Windtechnik extends and upgrades the existing contract for 61 Siemens turbines including major components

About Deutsche Windtechnik AG

Deutsche Windtechnik AG offers a single-source full technical maintenance package for wind turbines in Europe, North America and Taiwan. The company operates both onshore and offshore.

More than 7,500 wind turbines with a rated output of more than 12 GW are serviced by over 2,000 employees as part of permanent maintenance contracts (basic and full maintenance). Its system engineering focuses on Vestas/NEG Micon, Siemens/AN Bonus, Nordex, Senvion, Fuhrländer, Gamesa and Enercon turbines.

Deutsche Windtechnik take occupational safety and environmental protection very seriously, so all of their services are certified in accordance with ISO 9001:2015, BS OHSAS 18001:2007, ISO 14001:2015.

Press contact at Deutsche Windtechnik AG

Karola Kletzsch

Mail: k.kletzsch@deutsche-windtechnik.com

Phone: +49 (0)421 - 69105 330